Cocoa Processing

AI for Precision Roasting. Consistent Liquor. Higher Yield.

Achieve more stable liquor quality, higher yields, and greater profitability with intelligent control of roasting, grinding, and liquor conditioning.

TiA® Cocoa Optimization

Final Quality Variability

3.5%

With TiA® AI

2.8 – 3.0%

AI Prescription:

Stabilize roasting temperature to reduce yield variability.

Fine-tune conching speed/duration to ensure consistent viscosity and flavor.

Optimize alkalization dosing to maintain target pH.

Variation Reduction

15 – 20% reduction in std deviation

Estimated Savings

€500K Annually

Cocoa Processing Challenges

Critical quality issues affecting premium chocolate production

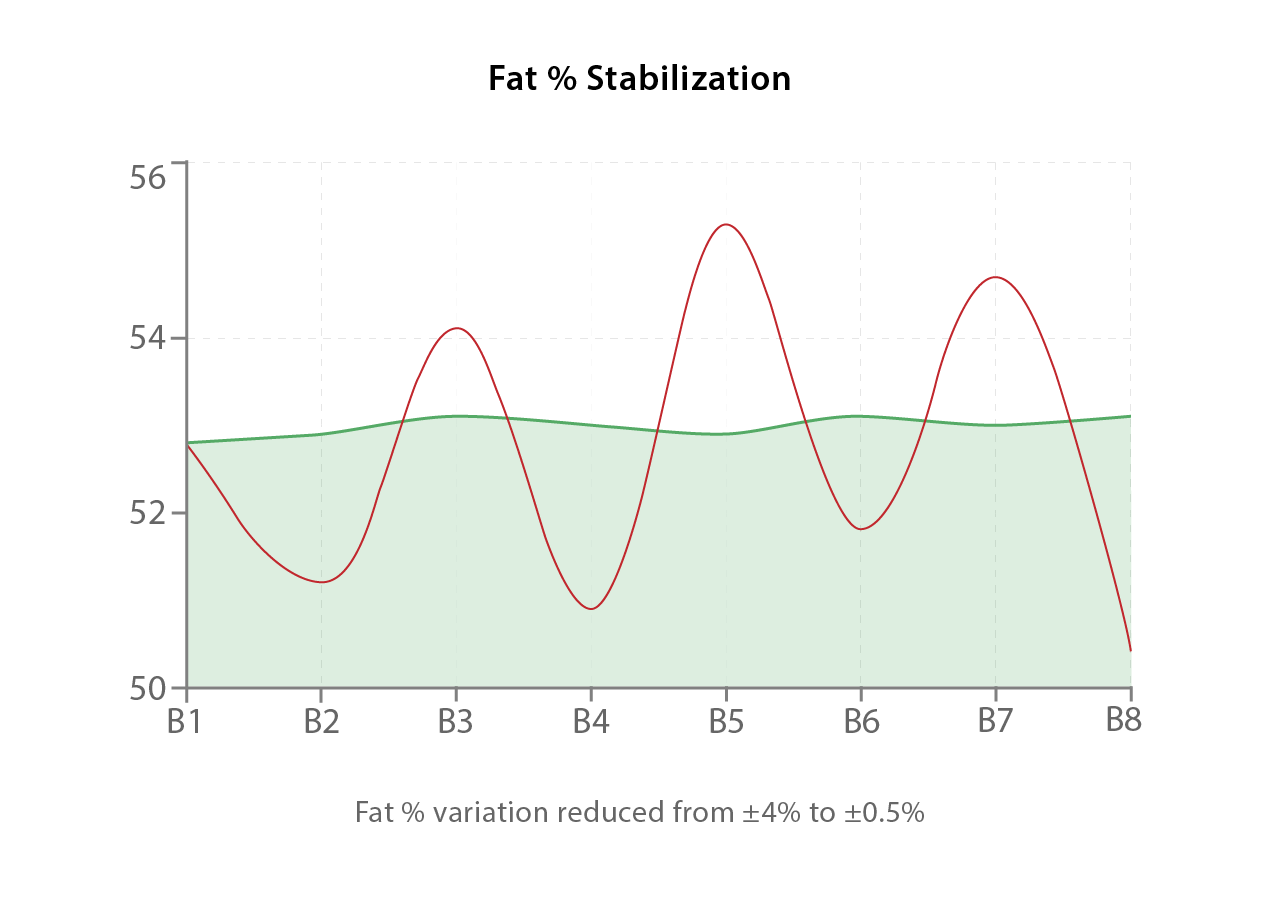

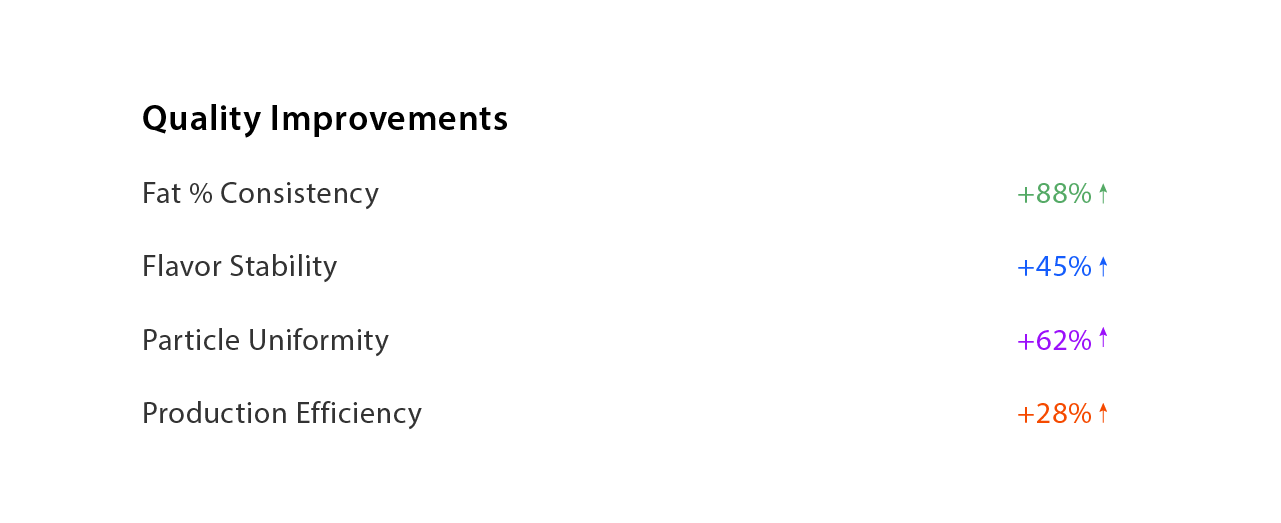

Fat % Variation

Inconsistent cocoa butter content affecting product quality

Current Impact

±4% deviation from target

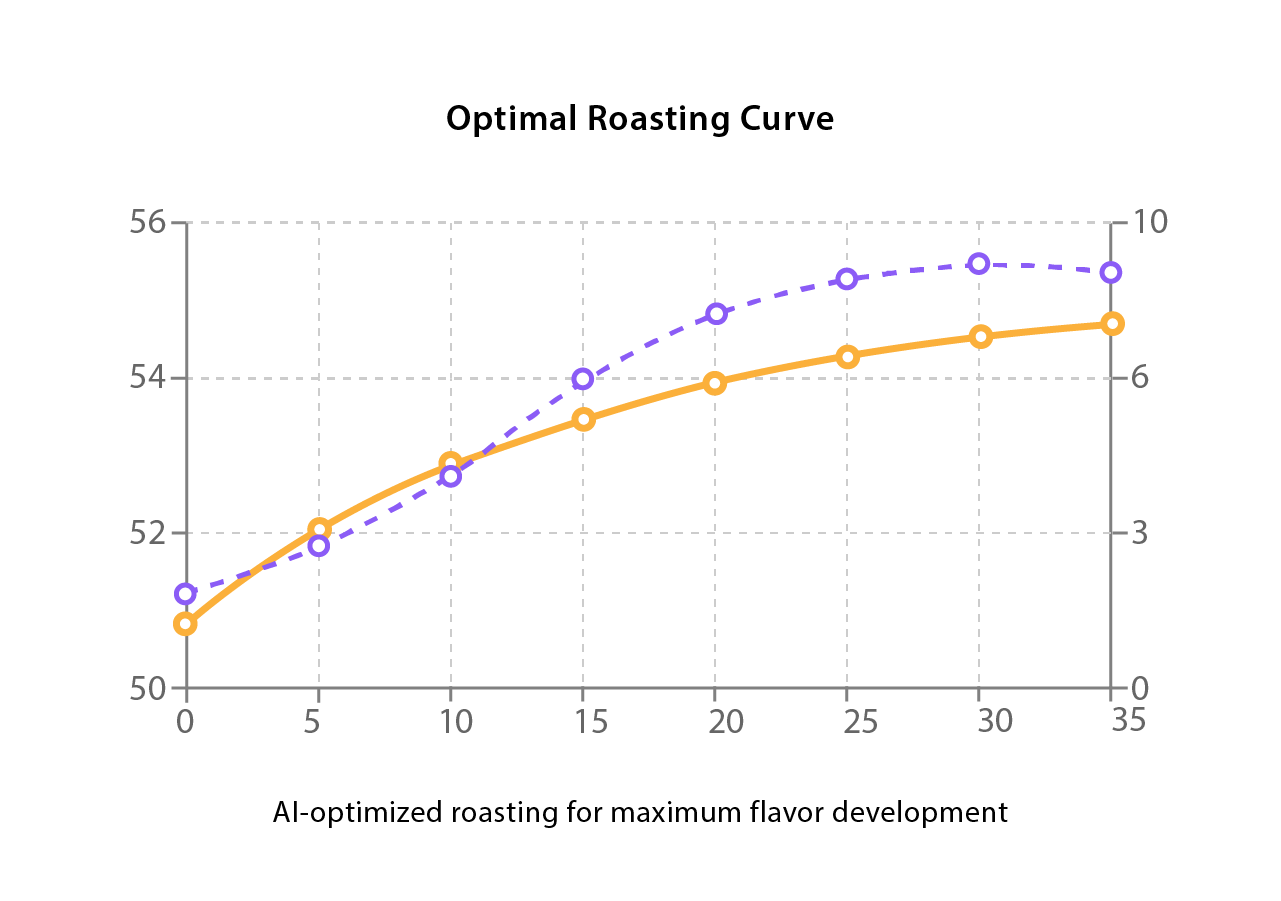

Roasting Inconsistency

Temperature and time variations impacting flavor development

Current Impact

25% flavor profile variation

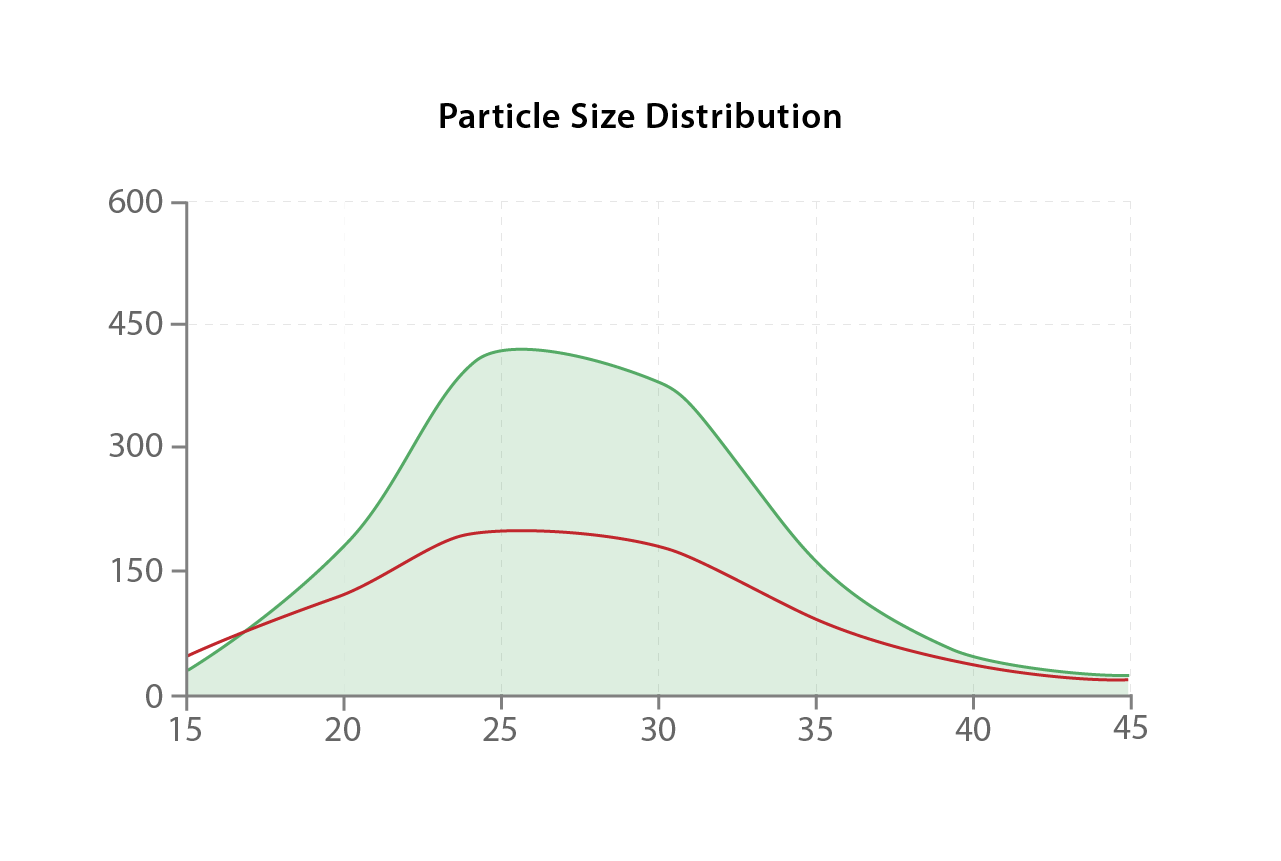

Particle Size Control

Grinding process variability affecting texture and mouthfeel

Current Impact

30% size distribution spread

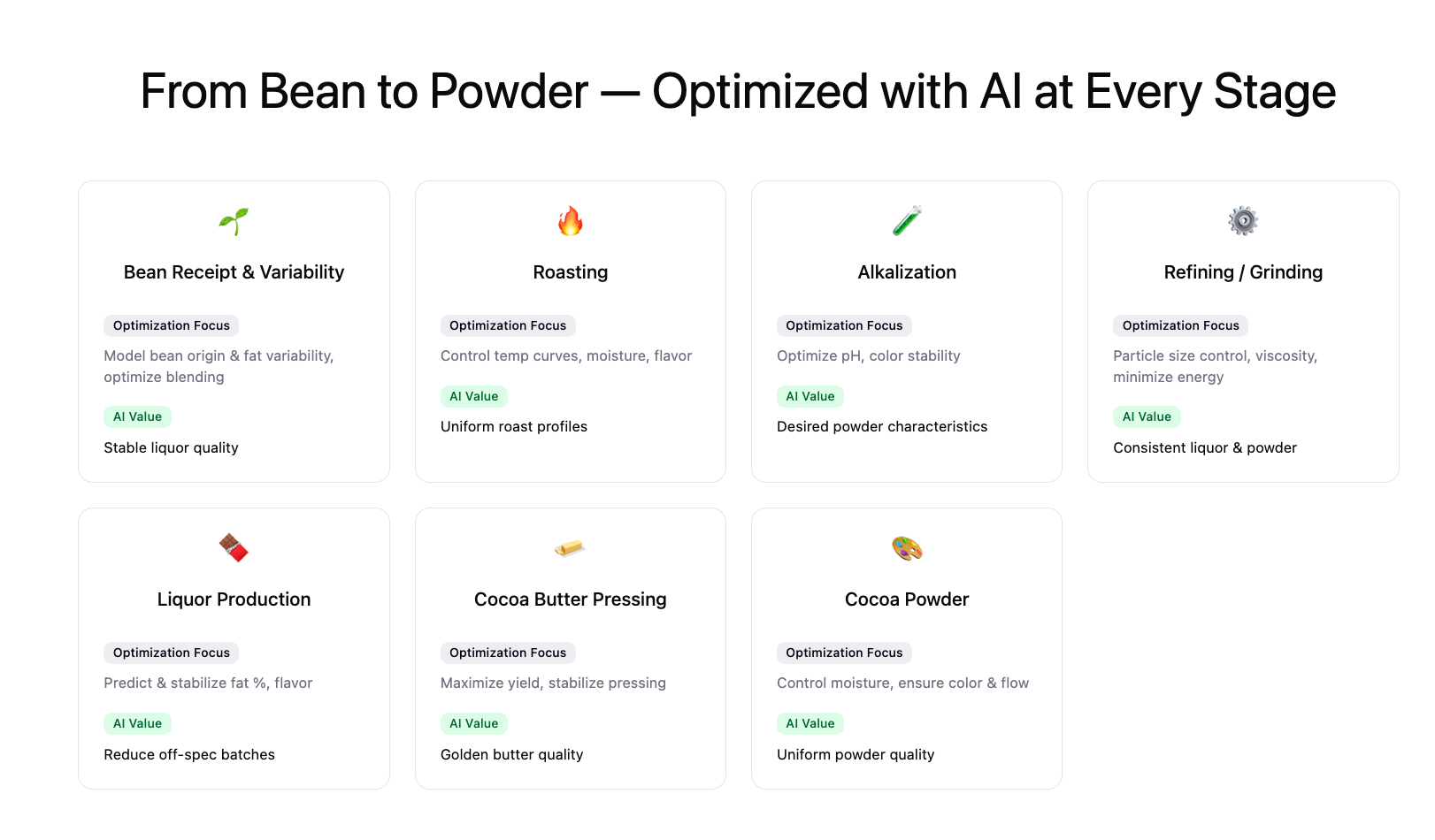

How TiA® Perfects Cocoa Processing

Precision AI for consistent flavor and quality

AI Prescriptions for Optimal Roasting

Dynamic temperature and time control that adapts to bean moisture content and origin for perfect flavor development.

• Real-time moisture monitoring and adjustment

• Origin-specific roasting profiles

• Predictive flavor development curves

Real-time Fat % Consistency

Continuous monitoring and adjustment of cocoa butter content during pressing and processing.

• Automated pressing pressure optimization

• Temperature-controlled fat extraction

• Real-time quality feedback loops

Golden Runs® for Best Yields

Replicate your highest-quality production runs with automated parameter replication across all batches.

• Particle size distribution optimization

• Conching time and speed control

• Texture consistency guarantees

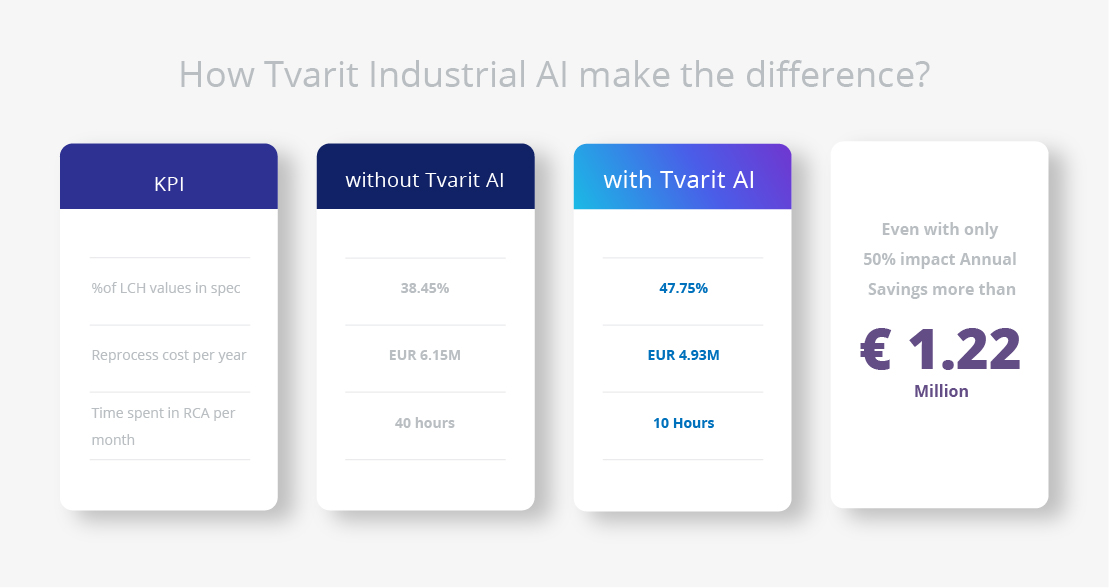

Success Story

Cocoa Value Chain Manufacturer Transformation

The Challenge

A cocoa processing company struggled with inconsistent liquor quality due to variations in moisture percentage, color (LCH) value, pH, alkalization, roasting profiles, and particle size—resulting in low in-spec rates, €1.2M in annual rework costs, and compromised product consistency.

TiA® Solution

Implemented across roasting, grinding, and conching processes with real-time fat monitoring, particle size analysis, and flavor profiling using advanced sensors.

€1.2M

Annual Savings

30%

Rework Reduction

47.75%

Higher In-Spec Rates

+25%

Stable LCH & pH Control

“TiA® helped us transform cocoa liquor production from reactive correction to proactive control. We now achieve consistent quality and higher in-spec rates, strengthening customer trust and brand reputation”

— Plant Manager, Cocoa Value Chain Manufacturer

How Tia Can Improve Your Processing Challenges