Chemical Processing

AI That Delivers Batch Consistency and Purity

in Chemicals

Eliminate batch variation, ensure reaction stability, and achieve perfect reproducibility with TiA® precision control systems.

TiA® Chemical Optimization

Current Purity

92.3%

Target Purity

97.0%

⚗️ AI Prescription

Increase reactor temperature by +2°C

Maintain pressure at 2.1 bar

Extend reaction time by +8 minutes

Yield

89%

Savings

€78K

Chemical Processing Challenges

Critical issues impacting product quality and profitability

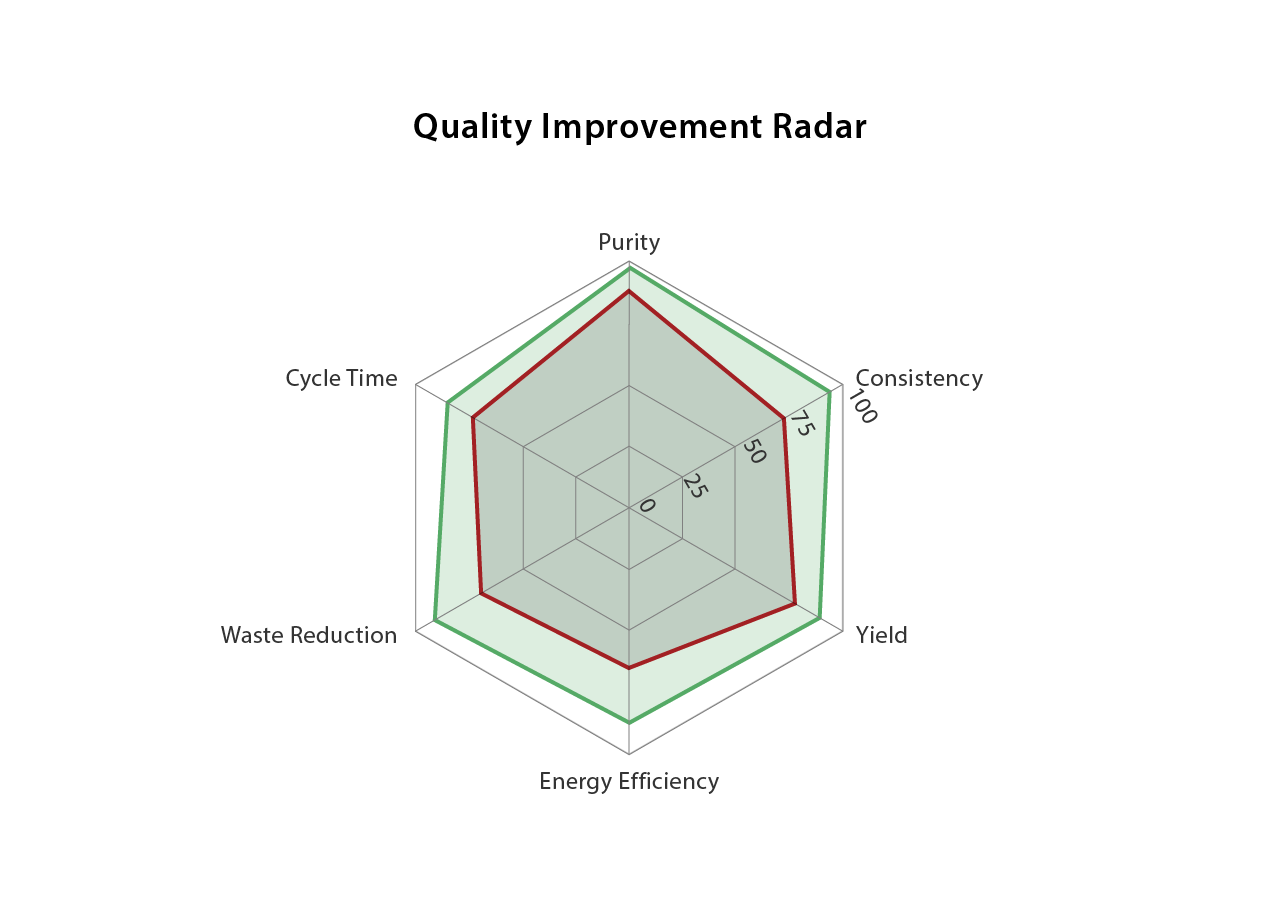

Batch-to-Batch Variation

Inconsistent product quality between production batches

Current Impact

22% variation coefficient

Purity Deviations

Product purity falling below specification limits

Current Impact

8% below target purity

Reaction Instability

Temperature and pressure fluctuations during synthesis

Current Impact

15% yield loss events

How TiA® Stabilizes Chemical Operations

Advanced AI for precise reaction control and quality assurance

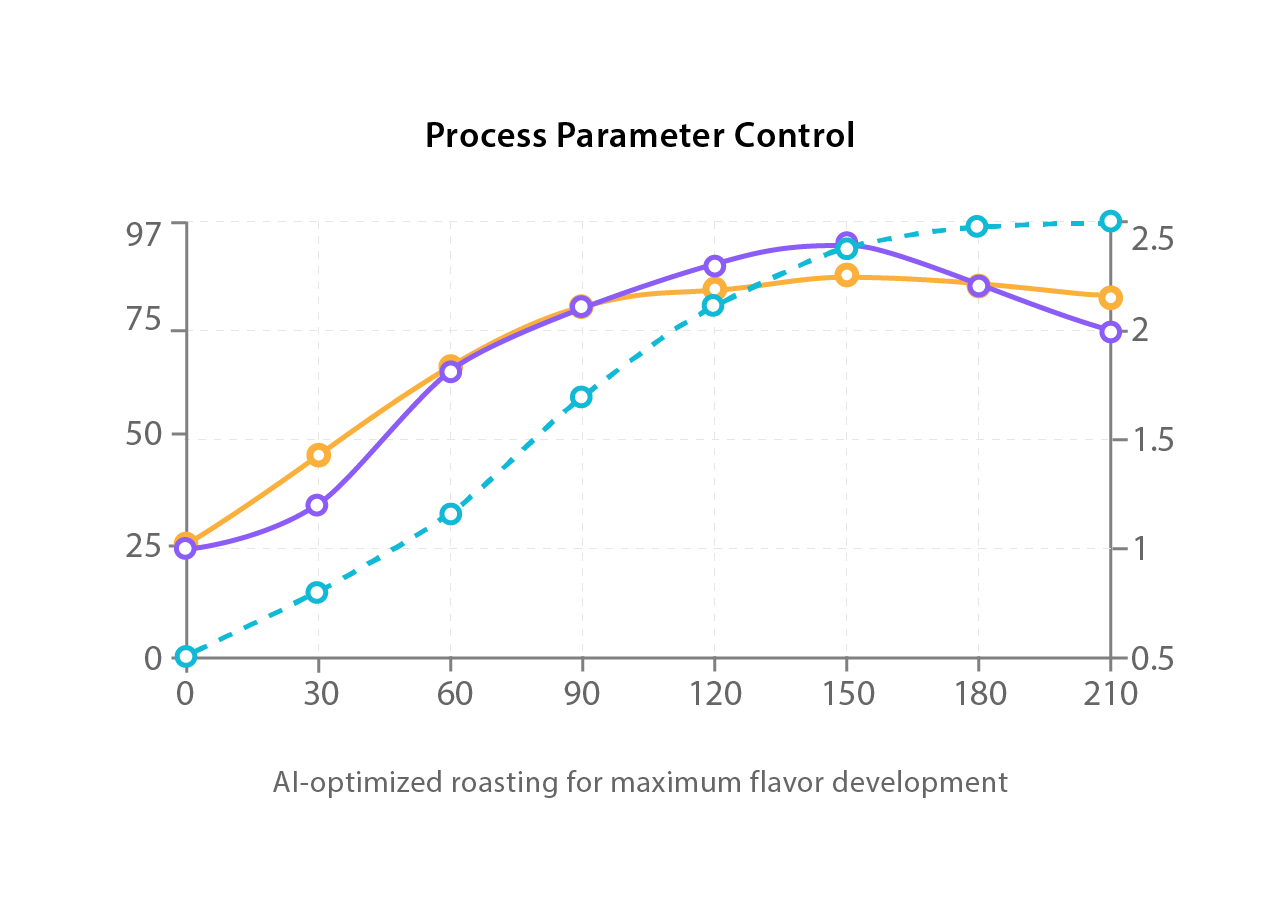

Real-time Prescriptions During Reaction

Dynamic parameter adjustment throughout the entire reaction cycle based on real-time process monitoring and predictive modeling.

• Continuous temperature and pressure optimization

• Real-time catalyst activity monitoring

• Predictive endpoint determination

Automated Root Cause Analysis

Instantly identify the source of quality deviations and batch failures with comprehensive correlation analysis.

• Multi-variable deviation tracking

• Historical batch correlation analysis

• Automated corrective action suggestions

Batch ID Tracking for Full Traceability

Complete genealogy tracking from raw materials to final product with automated quality documentation.

• Raw material lot tracking and correlation

• Process parameter history logging

• Automated compliance reporting

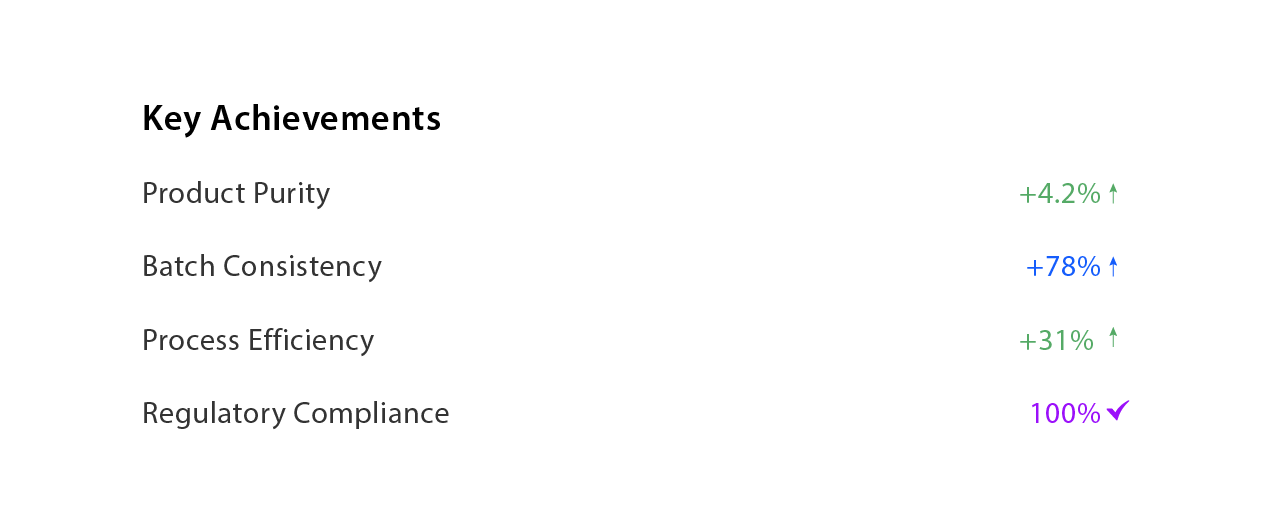

Success Story

Specialty Chemical Manufacturer Transformation

The Challenge

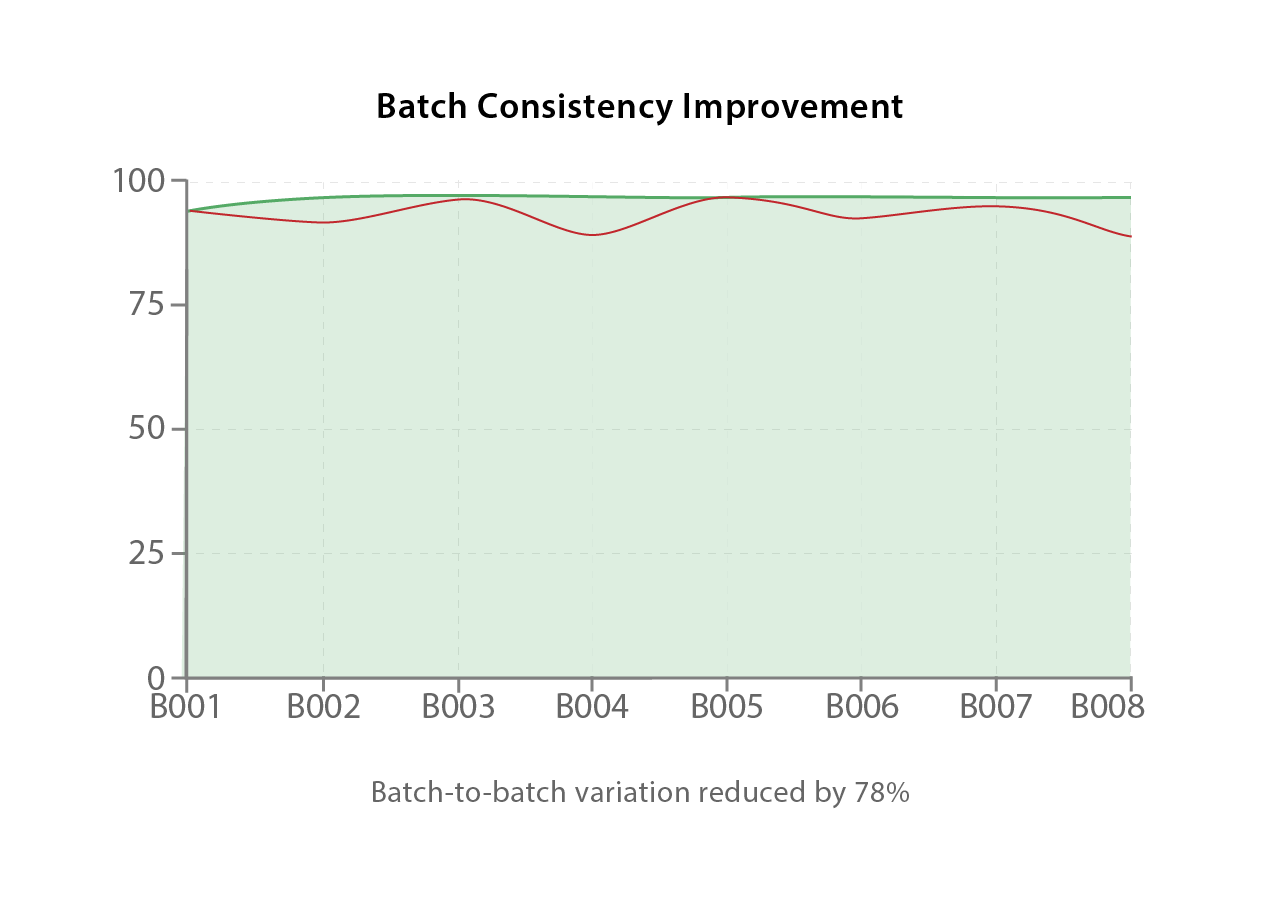

A specialty chemical manufacturer faced critical quality issues with 22% batch-to-batch variation and purity levels 8% below specification, risking regulatory compliance and customer contracts.

TiA® Implementation

Deployed across 6 reactor lines with advanced process monitoring, real-time optimization, and predictive quality control using machine learning algorithms.

4%

Purity Increase

50%

Rework Reduction

78%

Variation Reduction

4 Months

ROI Timeline

“TiA® transformed our chemical processes from unpredictable to precision-controlled. We now consistently exceed specification requirements and our regulatory audits are flawless.”

— Chief Process Engineer, Specialty Chemicals

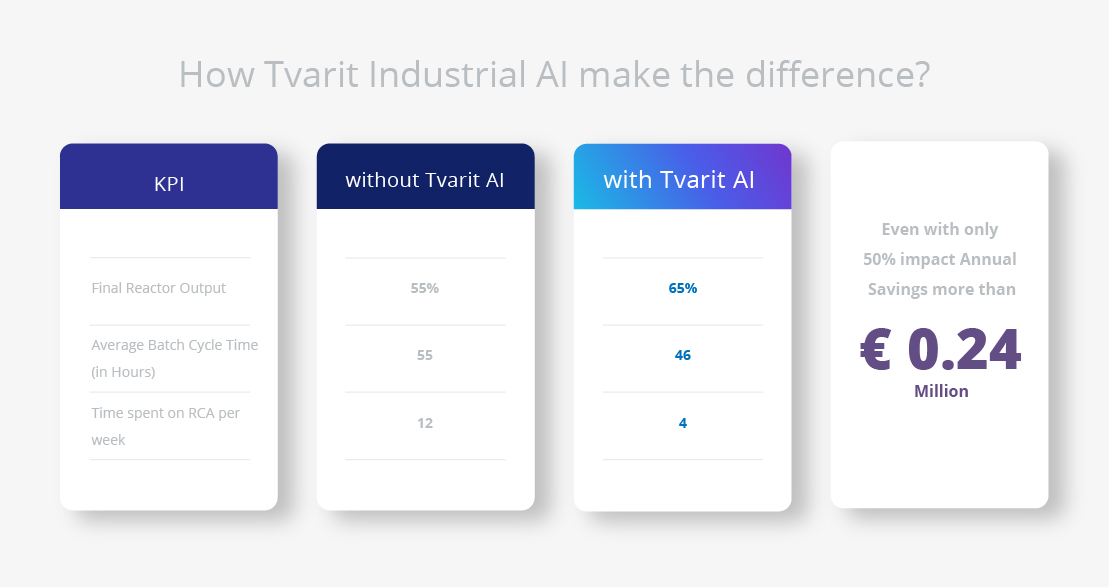

How Tia Can Improve Your Processing Challenges