Dairy Industry

From Variability to Consistency: AI That Maximizes Dairy Yield

TiA® standardizes moisture content, reduces process variability, and unlocks higher yields by identifying optimal “Golden Values” for key parameters.

TiA® Dairy Optimization

Current moisture variability

±1.8% (across vats)

Target Moisture Variability

±0.5% (within ideal spec range)

🥛 AI Prescription

Fine-tune milk temperature for ideal curd formation

Adjust rennet dose to enhance firmness and yield

Calibrate pressing stages for optimal texture and consistency

✅ Expected Savings

€42,000 per month

Dairy Industry Challenges

Critical issues affecting profitability across dairy operations

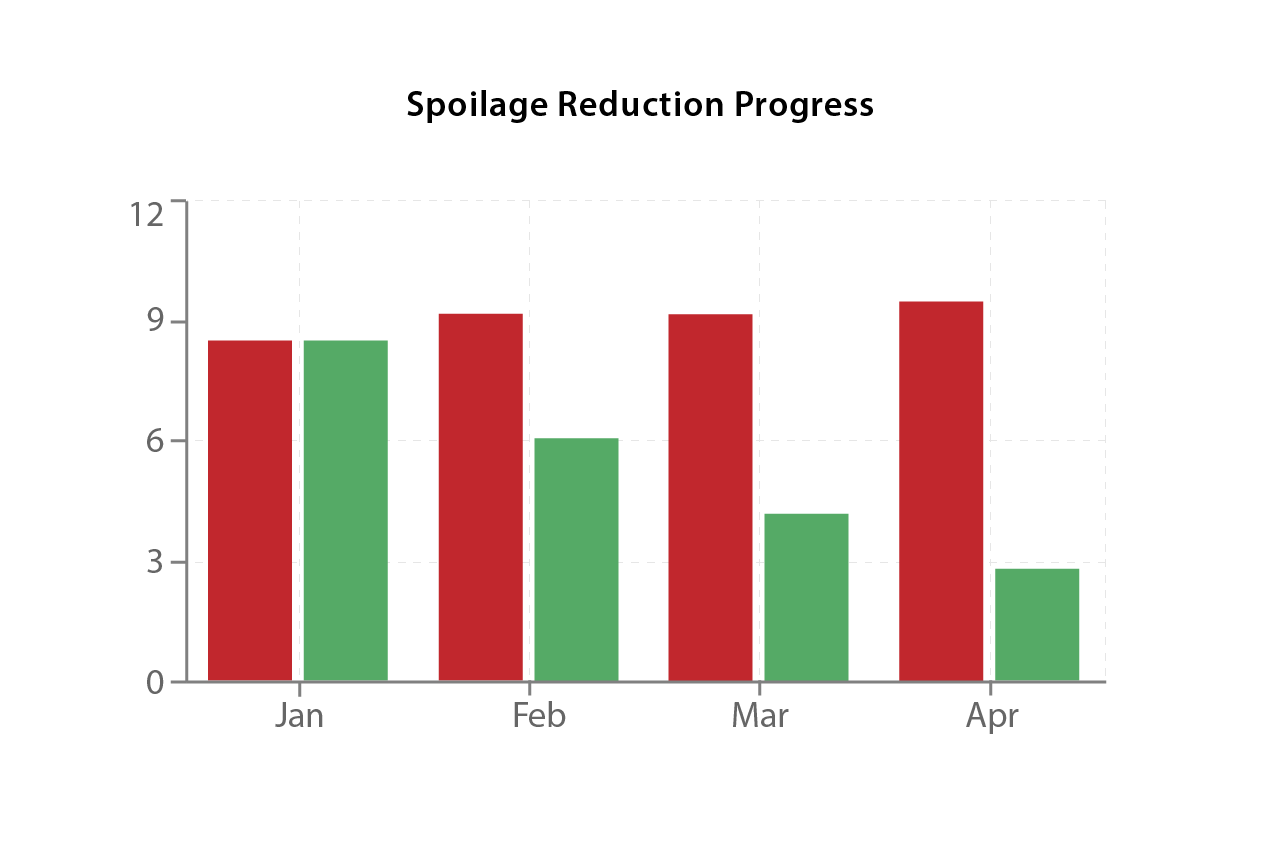

UHT Spoilage

Milk spoilage during ultra-high temperature processing

Current Impact

8.5% average loss rate

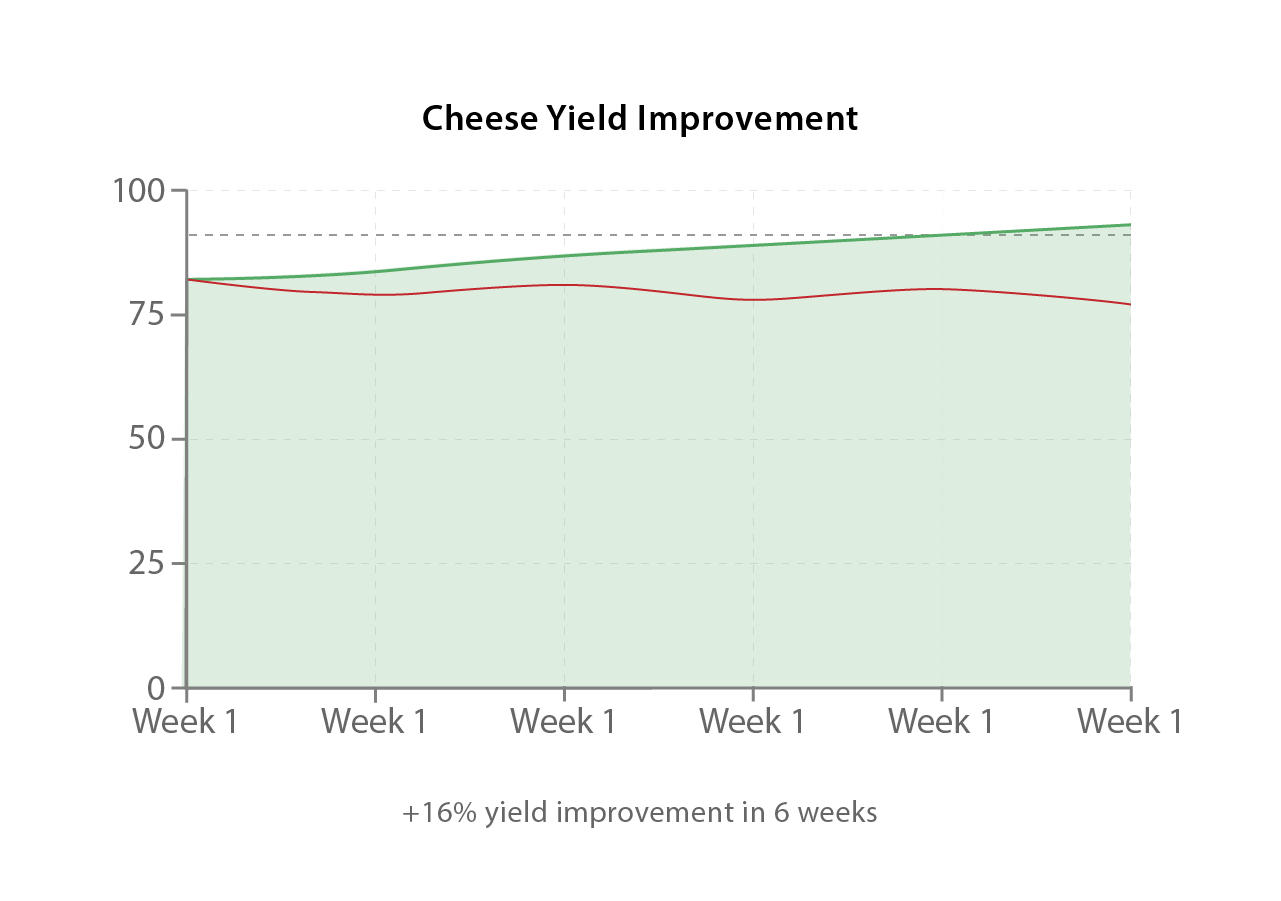

Cheese Yield Loss

Inconsistent yield in cheese

Current Impact

Up to 15% yield variation

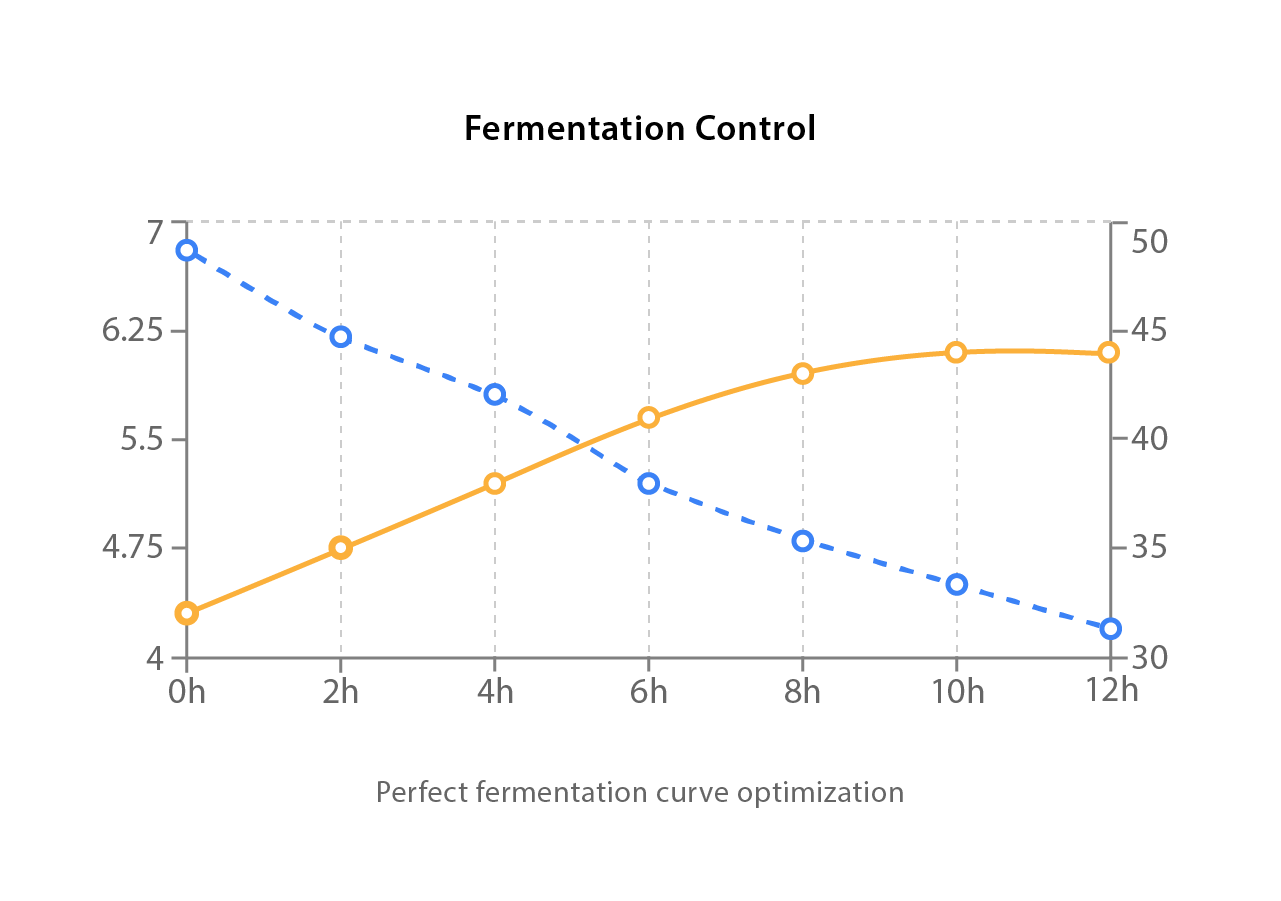

Fermentation Control

pH and temperature inconsistencies during fermentation

Current Impact

12% batch rejection rate

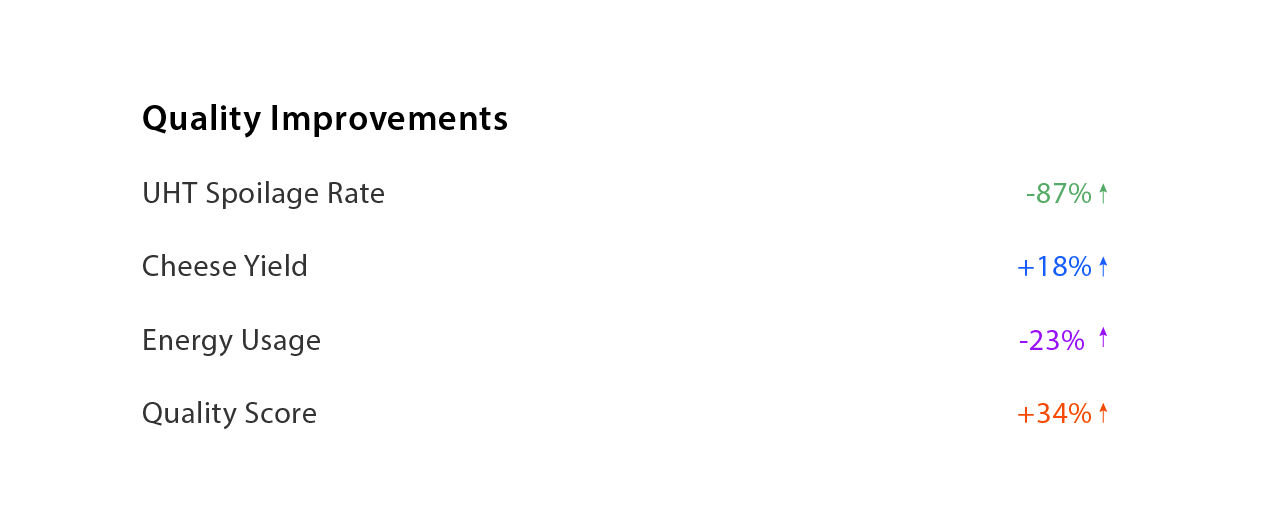

How TiA® Transforms Dairy Operations

Precision AI for every dairy challenge

Quality Consistency Engine

Maintain perfect UHT stability with real-time temperature and pH optimization that prevents spoilage before it starts.

• Predictive spoilage detection and prevention

• Optimal temperature-time combinations

• Real-time pH balance monitoring

Golden Runs® for Cheese

Replicate your highest-yield cheese production runs with automated parameter optimization.

• Maximum protein extraction efficiency

• Optimal coagulation timing

• Consistent moisture control

Fermentation Time Control

Perfect fermentation curves with AI-controlled temperature, pH, and timing for consistent results.

• Automated culture activity monitoring

• Dynamic pH adjustment protocols

• Optimal fermentation endpoint detection

Success Story

Cheese Plant Transformation

The Challenge

One of the Asia’s largest cheese manufacturer was losing €4.5M annually due to inconsistent yields, frequent spoilage, and fermentation failures affecting their premium cheese lines.

TiA® Implementation

Deployed on one cheddar production line with real-time monitoring of milk quality, fermentation parameters, and aging conditions using IoT sensors and AI optimization.

€4.5M

Annual Savings

+18%

Yield Increase

92%

Spoilage Reduction

16 Months

ROI Timeline

“With TiA®, we no longer ‘chase’ the right texture or moisture — the AI keeps us in the sweet spot. Our batches are consistent, and even seasonal milk changes are handled without drama.”

— Senior Production Manager, Cheddar Line

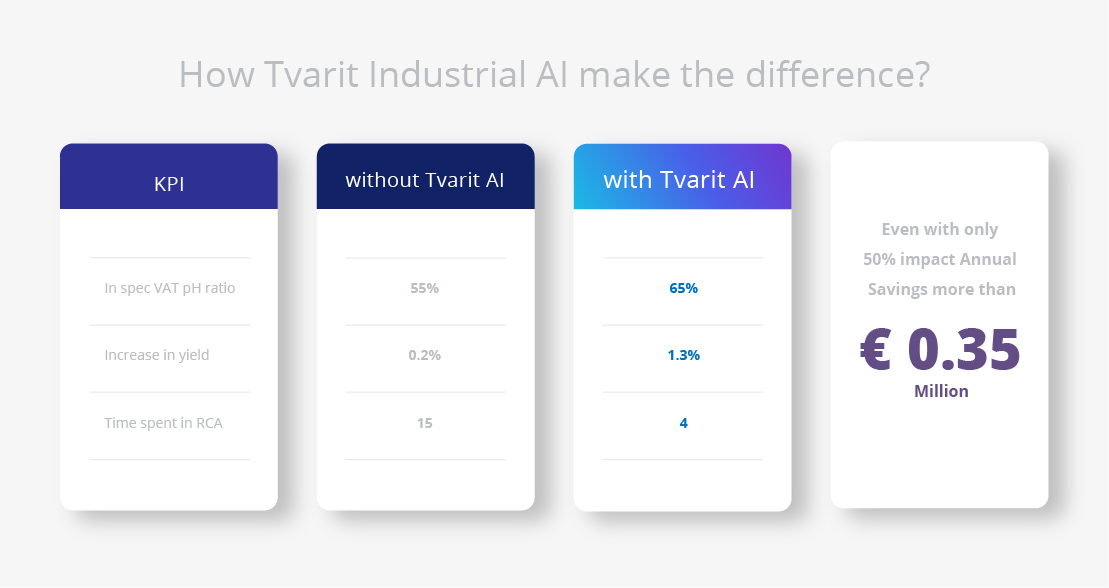

How Tia Can Improve Your Processing Challenges