Products

Readymade pre-trained AI products to solve your manufacturing challenges.

The Industries

where we have Experiences

Industries we have served

Industries we have served

Tvarit Industrial AI

Product Suite

Prescriptive

Quality

Reduce rejections with TiA® quality predictions, Error-Root-Cause-Analysis, and recommendations on measures to be taken by your operations team.

Furnaces

Molding

Casting

Machining

Prescriptive

Energy

Lower energy consumption and emissions with predictions of energy losses and recommendations on measures to reduce the dissipation of energy.

Ovens

Mixing

Furnaces

Smelting

Prescriptive

Maintenance

Prevent manufacturing disruptions and improve OEE by predicting optimal maintenance schedules & measures for all machines, utilities, & parts in your plant.

Tools

Cold Forming

Drive Motors

Milling

Prescriptive

Production Planning

Achieve energy efficient production planning including recommendations on optimal change-overs, and actionable advice on optimal scheduling of activities.

Paintshop

Inventory

Heat Treatment

Wire Drawing

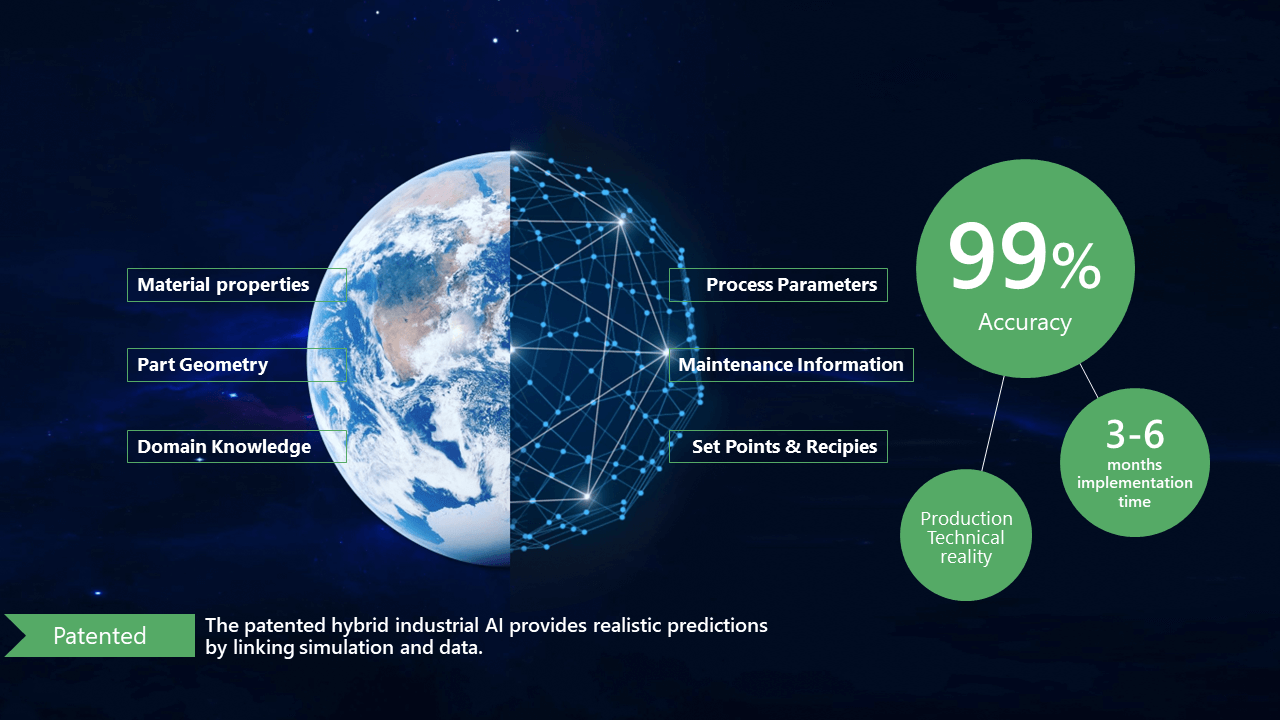

One-of-its-kind Hybrid AI Approach

with Domain-Specific Knowledge

By combining physical design simulations with AI modelling, our TiA® software gains unprecedented accuracy. With its realistic predictions, production can be optimized almost 100%.

Typical AI models use process parameters that come from PLC/DCS systems of various process equipment. But that’s just the tip of the iceberg. We dive deep into engineering designs. In this way, we can include information that can never be measured with shopfloor sensors. Therefore, conventional AI cannot replicate production processes. However, Tvarit hybrid AI models are able to simulate physical processes by taking into account information on input materials, maintenance, tools data, etc.

ANCHOR Benefits

Benefits

The Change we bring

Up to 1,500,000 € of annual savings

Up to 1,500,000 € of savings per plant

Up to 5% increased OEE

through increased productivity & improved yield

Up to 7,2 GJ reduced Energy per plant

due to reduced rework

Up to 60% improved yield

with suggestions for optimal casting parameters